From 2019 to 2025, the worldwide warehouse robotics market is estimated to increase at a CAGR of 11%. The warehousing industry is likely to see strong demand for robotic technologies to cut operational time and costs while increasing warehouse throughput. The market is expected to increase significantly due to rising need for automation, safety, and high-quality production.

Warehouse robotics is widely recognized as one of the most effective methods to minimize labor costs and improve operational efficiency. Among other jobs, the robots pick, place, transport, package, and palletize heavy items. The increasing use of IoT, AI, machine learning, and other similar technologies in the warehousing industry is expected to boost market growth in the near future.

The demand for specialist software to monitor staff, warehouse operations, and inventory flow has increased over the last decade. So software developers are constantly adding new features to software solutions. Many businesses utilize a Warehouse Management System (WMS) to manage inventory, manpower, and integrate ERP.

Retail and e-commerce growth, along with energy efficiency driven technical improvements in automation are projected to fuel the market. Several companies are using robotics and automation to build warehouses. In 2019, Amazon, Inc. installed over 100,000 robotic systems across 25 US fulfillment locations. It also deployed 800 Pegasus and Xanthus robotic systems in some fulfillment facilities and increased its global robotic drive to 200,000 robots.

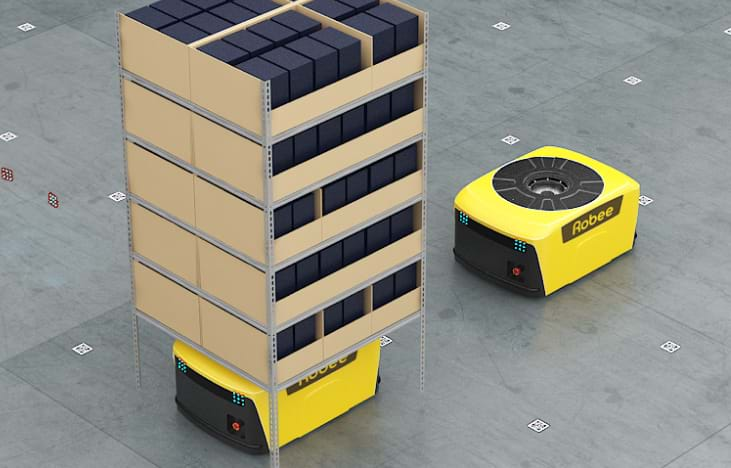

The use of robotic systems in facilities is predicted to increase from 2019 to 2025 due to increased employee turnover and a labor shortage. Collaborative robots (Cobots) are gaining popularity in warehousing because they improve security and simplify the human-machine interface. These clever cobots can replicate a warehouse task after seeing it done by an operator once.

The mobile robotics category accounted for over 25% of sales in 2018 and is expected to increase rapidly during the projected period. Mobile robots are a crucial part of the worldwide warehousing business, since they are utilized to move tiny payloads across the facility, especially in retail and consumer electronics.

In addition to material handling, picking and placing, and loading and unloading, cartesian robots are predicted to increase rapidly over the forecast period. Due to their meticulousness in doing laborious jobs, articulated robots held a significant market share in 2018. From 2019 to 2025, the segment is expected to grow at a CAGR of around 9%. This rise is ascribed to their ease of alignment and operating and maintenance simplicity. Due to their excellent accuracy and speed, SCARA robots are predicted to grow significantly over the forecast period. Parallel and cylindrical robots are becoming less popular due to their complexity and the availability of more advanced alternatives.

Payload Capacity Data

The sub-10 kg payload segment had a 30% revenue share in 2018 and is expected to continue dominating from 2019 to 2025. This is because smaller payload robots can transport the majority of things in a typical facility serving multiple end-use industries.

Operators rarely deploy robots with payload capacities of 400 kg and more, thus the growth rate of segments 401 kg to 900 kg and beyond is expected to be slow in the coming years. Automakers and consumer electronics companies invest in robots with payload capacities of 11 kg to 80 kg. In 2018, this segment had a market share of over 25%.

Insights

Customized software solutions for the warehousing and logistics business are being developed. Most of these systems provide a live visualization of the system’s components. It shows the state of online robots, storage shelves, pick stations, and recharge stations. This includes the shelf ID and the goods currently stored on it. These software tools allow facility staff inspect robots and instruct them to perform duties. The program may also detect problems with the robotic system and fix them.

Due to its ability to monitor overall activities and operations within a facility, Warehouse Management System (WMS) software commanded a sales share of over 40% in 2018. These procedures include order selection, receipt, put-away, cycle counting, and shipping. This is due to the fact that many organizations are investing in these solutions, which help them manage customers and the facility’s complexity.

Apps Insights

The e-commerce segment is driving the market growth because to an increase in online shoppers and their increasing needs for fast, accurate delivery of orders, as well as increased competition. The healthcare segment, on the other hand, is predicted to grow at the fastest rate, exceeding 13% during the forecast period. Increasing investments in robotic systems to automate distribution facilities for enhanced efficiency and safety are likely to drive significant growth in the food and beverage and automotive segments.

The pick and place category led the warehouse robots market in 2018 and is likely to continue leading during the forecast period. In 2018, the packaging segment accounted for almost 25% of the market, as many organizations use robotic systems to improve packaging efficiency and future-proof packaging. Companies are deploying robots to pack cases and to put containers into Form Fill Seal (FFS) machines.

Warehouse robots for transportation is in high demand due to the need to reduce transportation costs and improve loading and unloading efficiency. The warehouse industry’s fastest growing segment. The majority of products to be shipped are stacked to the ceiling on the container’s floor. When this consignment arrives at the distribution center, it is unloaded, sorted, and stacked on distinct pallets.

Companies are using robotics to bypass this labor-intensive process. Such a parcel robot from DHL International GmbH has a chassis, 3D laser scanner, telescopic conveyor belt, and grabbing system with articulated robot arm and grabber. This robot unloads the container and scans all boxes with its laser. Operators are automating difficult chores like hand palletizing with a robotic arm, freeing personnel to focus on value-added tasks.

North America led the warehouse robotics market in 2018 and is anticipated to continue leading during the forecast period, owing to faster adoption of new technologies and the importance of warehouse workers. The Europe market was worth over USD 650 million in 2018 and demand is expected to be slow in the coming years. La sluggish growth rate is due to severe market competition, industry saturation, and a difficult From 2019 to 2025, Germany is predicted to grow rapidly in Europe.

From 2019 to 2025, Asia Pacific is expected to be the fastest-growing region, driven by expanding output and local demand. Moreover, the region’s strong economic growth has increased the use of warehouse robotics in retail and industry.